“A lot of work was invested before I was able to control these reactions”

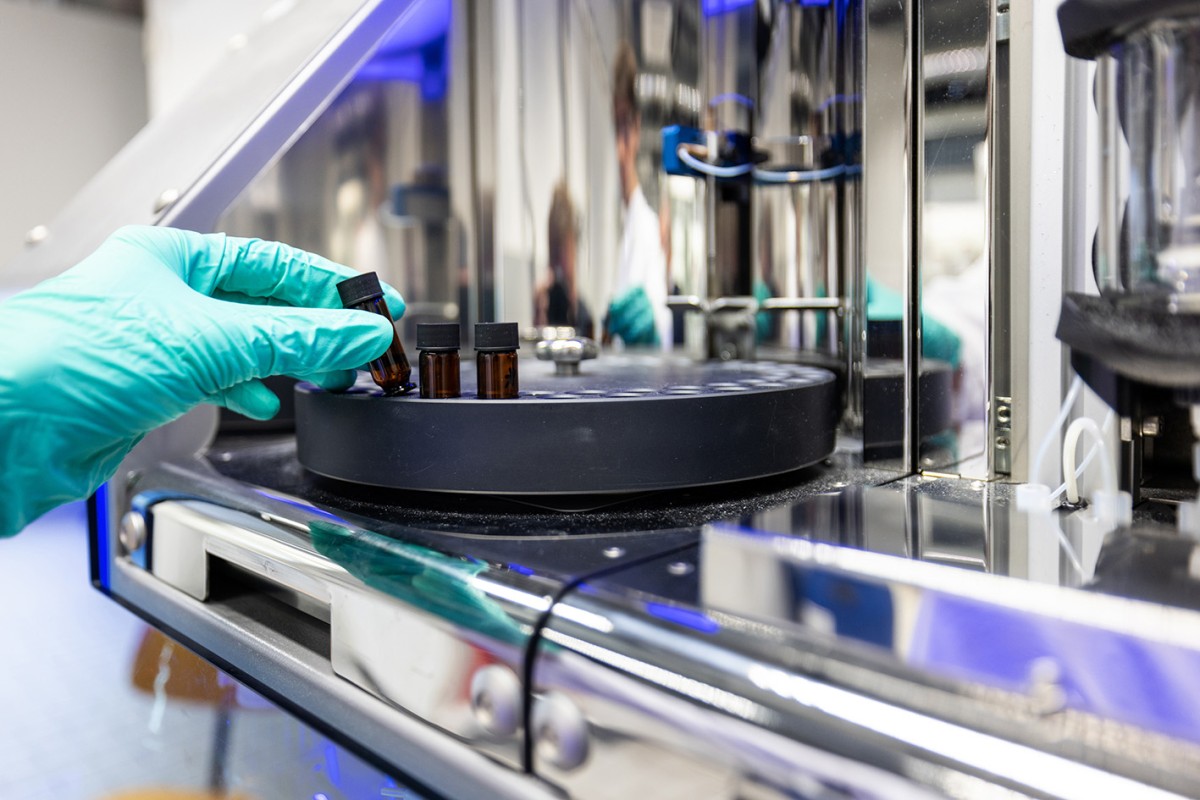

One project, one researcher and five years of intensive work: as part of her doctoral thesis, supervised by Prof. Ryan Gilmour at the Institute of Organic Chemistry, Dr. Charlotte Teschers has successfully developed a new method of producing complex, fluorinated sugars. For this purpose, she used a specially engineered instrument which produces carbohydrates in an automated fashion – a “Glyconeer”. In this interview with Christina Hoppenbrock, Charlotte Teschers – who is currently a post-dcotoral research fellow at the “Technion - Israel Institute of Technology” in Haifa – explains why sugar chains are so important in bio-medicineand why producing them is so complicated, despite having this unique machine.

Carbohydrates are something we associate with cornflakes and pasta. What, for a chemist, is so interesting about carbohydrates?

These sugar chains, which we also call glycans, are incredibly versatile – perhaps, actually, the most structurally and functionally versatile class of biomolecules in nature. Short sugar compounds are sources of energy. Long glycans can provide structure, one example of this being cellulose in plants. However, we often overlook the many other roles that carbohydrates have in an organism. For example, a wide range of different sugar patterns are to be found in connection with proteins on the surface of cells (so called glycoproteins). One of their roles is in recognising cells through immune responses. We’re a long way from knowing everything about the function of carbohydrates in the body – and there’s a lot which is difficult to research. Glycans are used not only to mark molecules, and thus make biochemical processes visible in living cells, but they are also important components of modern pharmaceuticals. Glycans are exciting candidates for potential new active ingredients in drug discovery.

What is so special about “your” glycans?

The glycans which we produced – and we were the first to do so using automation – are called fluorinated “glycomimetics”. The word includes the term “mimetics”, which is a form of camouflage which is achieved by simulating the native carbohydrate. Glycomimetics have an almost identical appearance to natural sugars and, from a chemical point of view, also behave like them. However, they are particularly stable and do not enter into unwanted reactions as much as natural sugars do. The trick we use is to integrate a fluorine atom. Whilst natural sugars are prone to degradation, the “biomimetic” variant is more stable and this enables us to gather information, for example: Where exactly does the sugar bond to a protein? How does this bonding function in detail? The fluorinated sugar is much more amenable to structural analysis. Besides which, you need to have stable glycans if they are to be used for labelling purposes or as active ingredients in drugs.

Why is automation of any interest in basic research? After all, you don’t want to produce large quantities of any substances …

It’s a false assumption that we use automation to produce large quantities. On the contrary, we can produce around ten times the amount using conventional methods, i.e. with traditional synthesis.

So the reason for automation is not that large quantities of the individual sugars are needed?

Right. It’s rather that the equipment helps us to produce a lot of different new sugars quickly and easily. On the basis of theoretical considerations, you can roughly predict which sugar you’re going to need for a certain purpose. But in most cases the precise type is not known, and, because there are a lot of small differences in a sugar chain, there are countless variants that could be considered. Using the equipment, I can compile a so-called library of these variants within about a week. Conventional synthesis for just one of these sugar structures would take much longer than compiling the entire library using automation. The effect of the glycans in the library can be tested. When we know which variant is the suitable one, we can subsequently produce it using traditional methods.

But the “Glyconeer” is not a new invention. Why did your work present such a challenge?

Appearances can be deceptive: the problem of producing carbohydrates hasn’t yet been solved by any means. Although the method involving automation has already been in existence for about twenty years, there aren’t many research groups working with it. Not counting Ryan Gilmour’s group, there are perhaps just a handful worldwide – and the company which sells the instrument (GlycoUniverse based in Potsdam) only manufactures on request. In particular, it’s the large range of glycomimetics, which I’m working on, that hasn’t been investigated very much. DNA, for example, can easily be produced using automation: you put the necessary ingredients together, and the machine does the rest. In the case of glycans, it’s not so simple. One problem is that every reaction can always result in at least two different variants of the product – with minute, but crucial, differences as far as the function and the effectiveness of the molecule are concerned. A lot of work was involved before I was able to control the reactions in such a way that only the desired variant resulted from them.

Who benefits from the method you have developed?

Anyone who is engaged in research into glycans now has a larger playing field to run around on. What we also hope is that anyone who has not yet worked in this area will also benefit – because glycomimetics are often easier to handle, due to their chemical properties, and can be used in living cells where the fluorine atoms confer a range of advantages. This is an aspect which is of particular interest for biomedical researchers.

Original publication:

Charlotte S. Teschers, Ryan Gilmour (2022): Fluorine-Directed Automated Mannoside Assembly. Angewandte Chemie International Edition; DOI: 10.1002/anie.202213304

This article is from the university newspaper wissen|leben No. 8, 21 December 2022.