Sugar-based Binders Enable Aqueous Cathode Processing

A ban on perfluorinated and polyfluorinated alkyl substances (PFAS) is currently being discussed in the EU, as the chemicals accumulate in organisms and the environment due to their high persistence and are hardly degradable. These substances are also used as electrode binders in battery production. Biopolymers, especially polysaccharides, are a sustainable and degradable alternative. In a recent study, scientists from MEET Battery Research Center investigated the extent to which these sugar-based groups, known from food chemistry and pharmacy, can be used as functionalized binders for the aqueous processing of nickel-rich lithium nickel cobalt manganese oxides (NCMs) as cathodes in high-energy lithium-ion batteries (LIBs).

Modified polymer binders improve NCMs

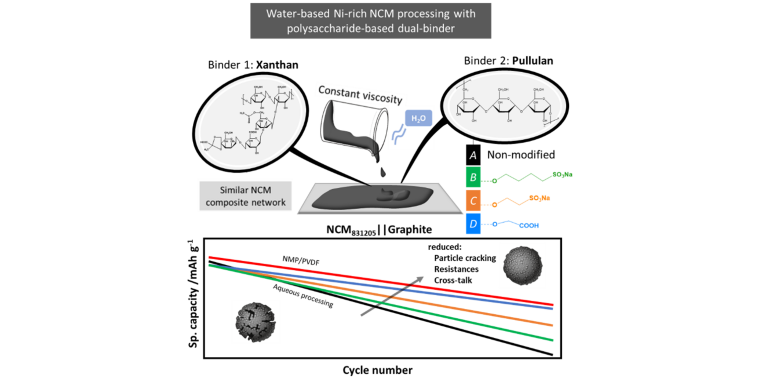

The degradation of the water-sensitive nickel-rich layered oxide cathodes (NCM), which has a negative effect on the cycle life of the cells, is still a challenge for research and development. In addition to coatings and processing additives, customized binders can also affect the performance of the battery systems. "In order to systematically investigate the influence of the differently modified, anionic binders on the charge/discharge cycling without any interference from changes in composite network, we selected high-viscosity xanthan and low-viscosity pullulan. Both polymers combined have a constant viscosity, so that comparable performance analyses are possible," says MEET scientist Simon Albers, explaining the dual-binder research approach.

One of these functionalized binders positively influenced the NCM||graphite cycle life, with a higher degree of substitution of carboxymethylated pullulan even competing with N-methyl-2-pyrrolidone/polyvinylidene difluoride state-of-the-art system at conventional upper charging voltage of 4.2 V. "Our research has shown that aqueous, sustainable battery production can keep up with conventional battery production processes in terms of cell performance," summarizes Dr. Johannes Kasnatscheew, Head of the Materials Research Department at the MEET Battery Research Center, the results of the study.

Detailed Results Online Available

The complete study has been published by the authors Simon Albers, Jens Timmermann, Tobias Brake, Anindityo Arifiadi, Anna Isabella Gerlitz, Dr Markus Börner and Dr Johannes Kasnatscheew, MEET Battery Research Center, as well as Prof. Dr Martin Winter, MEET Battery Research Center and Helmholtz Institute Münster in the journal “„Advanced Energy & Sustainabilty Research”.