Nickel-rich “Single-Crystal” Particles Increase Lifetime of Lithium-ion Batteries

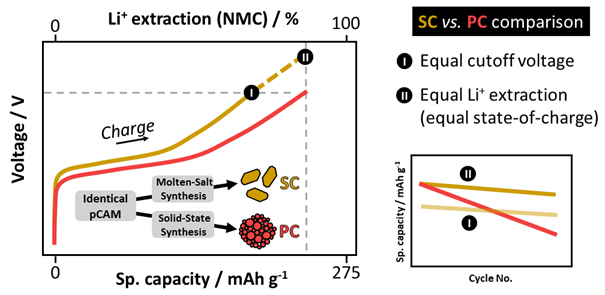

Modifying the particles of nickel-rich lithium-nickel-cobalt-manganese-oxide (NCM) cathodes is an effective method to increase cycle life of lithium-ion batteries. State-of-the-art NCM usually consists of micron-sized secondary particles, so-called polycrystalline (PC) particles, which are agglomerates of hundreds of nanometer-sized primary particles. Research is currently moving in the direction of so-called ‘single-crystal’ (SC) particles, which are also agglomerates by separated micron-sized monolithic particles. This mechanically more stable approach prevents the repeated break-up of the particles during battery cycling and is especially suitable for nickel-rich NCM, which is particularly plagued by this problem. As part of a German-Taiwanese research collaboration, scientists from the University of Münster and the National Taiwan University of Science and Technology have now systematically compared PC- and SC-NCM to investigate the advantages this approach could offer for nickel-rich NCM.

Fair comparison of “Single-crystal” and Polycrystalline Particles

The synthesis starts from the same precursor material, so that apart from the desired difference in particle shape the materials have comparable properties. Furthermore, the charge/discharge cycling conditions had to be adapted so that all materials had the same state-of-charge. The kinetic limitation of the ‘single crystal’ materials leads to a lower initial state-of-charge, which per se can have a positive effect on the cycle life. “By keeping the state of charge constant and not the voltage limits as usual, we prevent possible misinterpretations”, says MEET scientist Marco Joes Lüther. “In combination with the choice of synthesis, this approach ensures that the increased cycle life can be attributed solely to the ‘single crystal’ particles.” Dr. Johannes Kasnatscheew, Head of the Division Materials at MEET Battery Research Centre, adds: “Our approach can now also serve as a template for systematically comparing other cathode materials.”

Entire Study Available Online

The detailed results have been published by the authors Marco Joes Lüther, Dr Aurora Gomez-Martin, Julius Buchmann, Dr Richard Schmuch, Dr Tobias Placke and Dr Johannes Kasnatscheew, MEET Battery Research Center, Prof. Dr Martin Winter, MEET Battery Research Center and Helmholtz Institute Münster, Dr Martin Alexander Lange, Institute for Inorganic und Analytical Chemistry of the University of Münster, as well as Shi-Kai Jiang and Prof. Dr Bing Joe Hwang, National Taiwan University of Science and Technology, in the journal “Small Structures”. The work includes results from the “LiBEST2” research project funded by the Federal Ministry of Education and Research.