Modification of Nickel-rich NCM Cathodes

Nickel-rich layered oxides such as lithium nickel cobalt manganese oxide (NCM) with nickel contents up to 90 percent provide an increased energy density on material level compared to state-of-the-art materials. In addition, they require less cobalt as a critical raw material. They are therefore a suitable cathode material for high-energy lithium-ion batteries. However, the high nickel content also leads to material stress, which significantly reduces the lifetime of the battery cells. One approach to minimize the material stress is the modification of the cathodes via doping or coating with tungsten, for example. In a recent study, scientists from MEET Battery Research Center and the Institute of Materials Physics at the University of Münster have shown how the modification process can be efficiently designed and simplified.

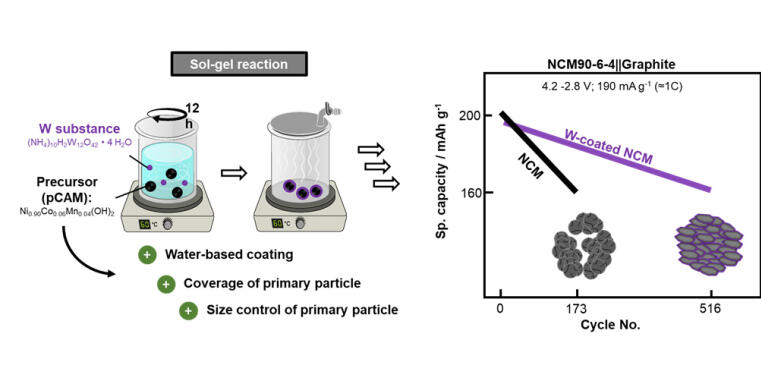

Coating the NCM Precursor with Tungsten

The current process is both, complex and expensive. To simplify it, the research team did not coat the NCM itself, but rather its precursor with tungsten. “As the precursor consists of hydroxides, it can be modified in water, which then simply evaporates,” explains MEET scientist Marcel Heidbüchel. The resulting NCM is not only characterized by an increased crystal stability, but also has an optimized mechanical stability due to the extended morphology of the primary particles. As a result, a lifetime of more than 500 cycles is achieved. In comparison: Previously it was around 200 cycles.

Dr Johannes Kasnatscheew, head of the research division Materials at MEET Battery Research Center, classifies the results: “On the one hand, we have shown that NCM can be used as a cathode material with a nickel content of up to 90 percent without much additional effort. On the other hand, the importance of the morphology of the primary particles for the mechanical stability and lifetime of the battery cells became evident.” The scientists thus make an important contribution to research on next-generation cathodes.

Detailed Results Online Available

The complete study has been published by the authors Marcel Heidbüchel, Dr Aurora Gomez-Martin, Lars Frankenstein and Dr Johannes Kasnatscheew, MEET Battery Research Center, Prof. Dr Martin Winter, MEET Battery Research Center and Helmholtz Institute Münster, as well as Ardavan Makvandi, Dr Martin Peterlechner and Prof. Dr Gerhard Wilde, Institute of Materials Physics at the University of Münster, in the journal “Small Science”. The work includes results from the "SeNSE" research project funded by the European Union's Horizon 2020 research and innovation program.