Influence of Activators on Graphitization of Sustainable Biomass Materials Identified

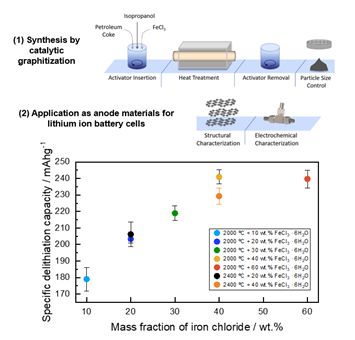

Graphite is currently the material of choice for anodes of lithium-ion batteries. Both natural and synthetic graphite are commercially used, yet there are raising environmental and supply bottlenecks concerns for the production of both types. A possible, sustainable precursor material for the production of synthetic graphite is the biomass product coffee grounds. However, biomass materials must be graphitized with the help of an additive in order to show competitive performance in battery cells. A team from MEET Battery Research Center at the University of Münster, the University of Seville, and Helmholtz Institute Münster of Forschungszentrum Jülich has systematically investigated the influence of the activator iron(III) chloride hexahydrate on the 'catalytic' graphitization process of coffee ground.

Development of Sustainable Synthetic Graphite Anode Materials

The scientists systematically investigated the graphitization of coffee ground using different amounts of the activator iron (III) chloride hexahydrate and varying the temperature range from 1,000 degrees Celsius to 2,400 degrees Celsius. "This allowed us to pay particular attention to how the synthesis conditions, for example temperature and mass fraction of iron, correlate with the electrochemical performance as anode materials in the battery cells," explains MEET researcher Vanessa Hanhart. Structural characterization showed that a mass fraction of 20 percent by weight of iron chloride hexahydrate combined with an elevated temperature of up to 2,000 degrees Celsius favored the graphitization of coffee ground.

MEET scientist Lars Frankenstein classifies the results of the study: "For the first time, a saturation point for the degree of graphitization was found when using iron chloride as activator and coffee ground due to the volatility of the iron source itself. Therefore, further investigations on different iron-based sources are needed to improve the graphitization efficiency of biomass materials". The saturation point was achieved when the activator accounted for 40 percent of the total weight by mass and was heat treated at 2,000 degrees Celsius. The research team's results provide an important basis for further studies on the influence of activators on the graphitization of biomass materials and gives significant insights into the impact of synthesis conditions.

Study Published in ChemElectroChem

Authors of the study are researchers Vanessa Hanhart, Lars Frankenstein, Dr Vassilios Siozios, Dr Aurora Gomez-Martin and Dr Tobias Placke, MEET Battery Research Center, Prof. Dr Joaquin Ramirez-Rico, Departamento Física de la Materia Condensada and Instituto de Ciencia de Materiales de Sevilla, Universidad de Sevilla, and Prof. Dr Martin Winter, MEET Battery Research Center and Helmholtz Institute Münster. The entire study was published in the journal "ChemElectroChem".